Mastercam 2025 Features: Comprehensive Guide to the Latest Machining Software

Introduction to Mastercam 2025

Mastercam 2025 has been released, bringing a host of new features and improvements that promise to enhance the efficiency and capabilities of CNC programming. In this article, we will explore the key features of Mastercam 2025, providing insights into how they can benefit your machining operations.

Visual Linking for 2D and 3D Toolpaths in Mastercam 2025

Visual linking is a significant enhancement in Mastercam 2025. This feature introduces on-screen markers that visually display linking parameters, giving a clear bird’s eye view of toolpaths. Users can quickly identify where their toolpaths go, which is particularly useful for understanding incremental settings in both 2D and 3D toolpaths.

Finish Passes for Dynamic Mill

Mastercam 2025 introduces the ability to add finish passes to dynamic mill operations. This means that after the roughing section, the tool can execute a finish pass along the walls, ensuring precision and reducing the need for separate finishing operations. This feature can significantly streamline programming by combining roughing and finishing into one toolpath.

Y-Axis Turning

Y-axis turning in Mastercam 2025 takes advantage of the stability of CNC machines by using tools with different orientations. This method distributes the cutting load more effectively into the spindle, enhancing rigidity and productivity. This feature is especially beneficial for complex parts that require stable cutting operations.

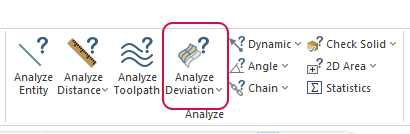

Deviation Analysis

The new analyze deviation tool in Mastercam 2025 helps users compare surfaces to ensure precision. By selecting reference and target surfaces, the tool displays deviations, allowing for adjustments to achieve accurate machining results. This is particularly useful for complex parts with multiple faces.

Saving Machine Configurations for Mill-Turn

Mastercam 2025 now allows users to save machine configurations for mill-turn operations. This feature stores information such as chuck settings, tool blocks, and tooling setups, enabling easy retrieval and application for different parts. It simplifies the setup process and ensures consistency across multiple operations.

Deburr 3-Axis Toolpath Add-On

Deburring has become more accessible with the Deburr 3-Axis toolpath add-on. This new feature brings the logic of multi-axis deburring into 3-axis operations, allowing users to deburr complex parts efficiently using ball endmills and lollipop tools. It saves time and enhances the quality of finished parts.

Improved Associativity for Toolpaths Against Mesh Models

Mastercam 2025 enhances associativity for toolpaths against mesh models. Changes to the mesh automatically update the toolpaths, ensuring accuracy and reducing the need for manual adjustments. This feature is crucial for maintaining precision in parts with intricate mesh structures.

Swarf Milling with the Tip of the Tool

Swarf milling with the tip of the tool is now supported in Mastercam 2025. This feature allows for precise control over chamfers and other intricate features, improving the quality of finished parts. Users can select specific tool orientations and apply swarf milling to achieve smooth and accurate results.

Workholding Updates

Workholding in Mastercam 2025 has been enhanced to provide better control and flexibility. Users can now define fixtures for specific operations and manage them through a dedicated workholding page. This feature simplifies the setup process and improves the accuracy of simulations and verifications.

A-Axis Turning

The new A-Axis contour toolpath in Mastercam 2025 allows for dynamic rotation of the tool around the A-axis during cutting operations. This feature is designed for B-axis style mill-turn machines, providing greater flexibility and precision in accessing complex features.

Bonus: Updates to Solid Hole Selection and Safety Zone Enhancements

Mastercam 2025 has also improved solid hole selection, allowing users to read hole geometry directly from solid models without needing additional steps. Additionally, enhancements to the safety zone for multi-axis drilling provide smoother and more accurate transitions, improving overall machining performance.

Conclusion

Mastercam 2025 brings a wide array of new features and improvements designed to enhance the efficiency and capabilities of CNC programming. From visual linking and dynamic mill finish passes to advanced Y-axis turning and improved toolpath associativity, these updates offer significant benefits for machinists and programmers. Stay tuned for more detailed guides and tutorials on how to leverage these features in your machining operations.

For more information on Mastercam 2025 and to see these features in action, explore our other articles and tutorials.

Mastercam 2025 brings a wide array of new features and improvements designed to enhance the efficiency and capabilities of CNC programming. From visual linking and dynamic mill finish passes to advanced Y-axis turning and improved toolpath associativity, these updates offer significant benefits for machinists and programmers.

To make the most of Mastercam 2025, consider reaching out to us for exclusive discounts, comprehensive Mastercam 2025 Training, and unparalleled support. We offer personalized in-person Mastercam training sessions, large discounts on software, and on-site support to ensure you get the best performance from your CNC operations. Our team is also ready to assist you with Verification support and special software deals tailored to your needs. You may be interested to join exclusive Machining Marketplace

Contact us today to learn more about how Mastercam 2025 can transform your machining processes and to take advantage of our exceptional offers. Don’t miss out on the opportunity to enhance your skills and efficiency with Mastercam 2025.