TRUSTED MACHINE SHOP SERVICES SINCE 1980

Our skilled staff has the experience and knowledge to handle your most technical and challenging jobs

PROTOTYPE THROUGH PRODUCTION MACHINING SERVICES

Trusted Precision Manufacturing Partner - Helping customers bring ideas to life with expert craftsmanship.

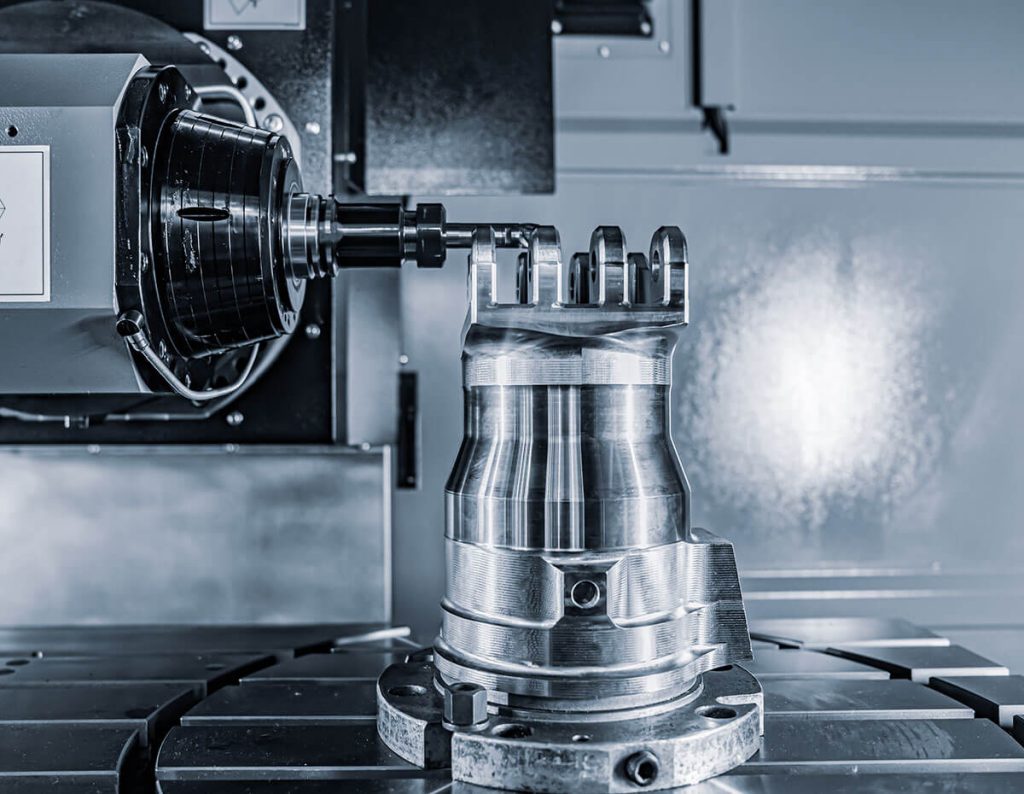

PRECISE MANUFACTURING

Our machinists continuously hone their craft to provide the most precise manufacturing possible. We regularly calibrate equipment and work to the tightest tolerances to ensure accuracy down to the ten-thousandth of an inch.

FAIRLY PRICED SERVICES

Are you tired of shops overcharging for basic machining and fabrication? Our streamlined and efficient processes allow us to offer very competitive rates without sacrificing quality.

DELIVERING ON YOUR TIMELINE

We understand that delays can hamper progress and cost money. That's why we pride ourselves on on-time delivery of parts and projects to help you meet your deadlines. Our quick turnarounds provide peace of mind.

MACHINING YOU CAN TRUST

Since 1980, we have become the trusted machining partner for leading manufacturers through decades of experience. Our expertise, reliability, and workmanship make us the preferred choice for long-term relationships.

About Us

At AD Precision, we are driven by passion for flawless execution and service that customers can trust. For over 40 years, leading manufacturers have relied on us as their precision machining partner to consistently deliver parts of unparalleled quality, competitive pricing, and on-time results.

People-Powered Manufacturing Excellence

At AD Precision, our tight-knit, family culture empowers employees to drive manufacturing excellence. Leveraging decades of experience, our passionate team provides bespoke tools, machines, and services tailored to clients’ needs. We design, build, and rigorously test every custom product to strict quality standards while delivering exceptional results at reasonable costs. Our people-powered approach focuses on understanding your goals to produce solutions that meet them.

Accelerate Time to Market

By partnering with us, you can increase profit margins and bring products to market faster, cheaper, and more efficiently.

Our capabilities allow you to rapidly prototype, test, iterate, and manufacture finished products. We’ve experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed.

Without a doubt, the people behind AD Precision are the cornerstone of our company’s success.

Machining Expertise Meets the Highest Standards

Our machining expertise accounts for every variable – workpiece orientation, workholding, feeds, speeds, and tool selection. Thoroughly determining all project parameters allows our engineers to meet unique specifications.

With control of each aspect, we achieve maximum accuracy and enhance material properties like flexure, stability, heat tolerance, and chip resistance.

Such precision capabilities are crucial for highly regulated industries requiring flawless performance of high-tech alloys in extreme environments. We provide the needed process control and metrology to manufacture components suitable for the most demanding applications.

Check out our work

For over 40 years we have specialized in the precision CNC machining of most metals, plastics, and engineering grade materials.

Industries

We serve industries and companies on the cutting edge of technology, continuously meeting their most complex and demanding requirements. Our team stands ready to work closely with customers to ensure their project is completed to their satisfaction.

We consistently deliver high-quality components for an ever-changing industry. With global electronics moving at the speed of design, we fulfill on time, every time.

With flawless precision, we manufacture critical components like turbine blades and landing gear for leading aerospace companies. Our capabilities meet the highest standards in machining exotic alloys for advanced aircraft.

National defense contractors count on our reliable supply of mission-critical components. We meet stringent standards for quality control and on-time delivery.

AD Precision meets the tight tolerances and rigorous standards in the fields of research and science. Our background and expertise across multitudes of industries and makes us the adaptable and flexible choice for any project.

Whether it’s heavy machinery in the field or a production line in a plant, equipment takes a pounding. We supply rugged, reliable components machined to endure intense vibration, corrosion, temperature swings, and frequent wear.

Automotive suppliers trust us to machine high-quality components for today’s complex vehicles. We handle high-volume production while meeting exacting OEM specifications.

Medical device makers rely on our precision manufacturing capabilities for lifesaving technologies. We deliver critical components built to high tolerances for surgical tools, implants, and more.

We machine quality components for housings, enclosures, and internals to meet changing standards. Our capabilities adapt to produce parts enabling the latest high-speed, high-performance data transmission gear. Trust us for machined communications components built for today and ready for tomorrow.

The energy sector is constantly evolving, and our machine shop is here to offer a wide range of services to meet the needs of the energy industry, including: components for turbines, generators, and other power equipment.

Capabilities

Through the use of state-of-the-art manufacturing equipment, AD Precision has the capabilities to provide clients with a variety of services including CNC and conventional machining, waterjet cutting, kitting, and assembly. Below, you can find a comprehensive list of the equipment we operate to fulfill manufacturing solutions for our customers.

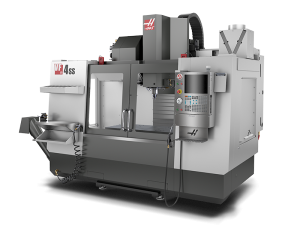

CNC MILLING

AD Precision has a large variety of milling machines to fit your precise needs.

Whether it is to machine a prototype with a quick turnaround time or production quantities on our horizontal palletized centers, 5-axis or vertical CNC machines

We continually acquire the latest machine technologies to offer the very best in accuracy and delivery times.

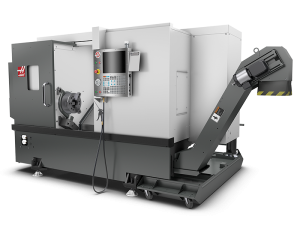

CNC TURNING

From swiss turning machines to large horizontal lathes, AD Precision has a wide variety of CNC lathes to meet your production needs.

With live tooling and multi axis lathes, AD Precision can machine complete parts in minimal machine set ups and offer dimensional control and accuracy.

MAX TURNING DIA: 45.7”

MAX TURNING LENGTH: 39.4”

TOLERANCE: Tighter tolerances to ± 0.0002 available, depending on part geometry.

CNC 5+AXIS

AD Precision is proud to offer 5-axis machining, the ability to machine complex parts fast and with high accuracy. Our 5-axis machining allows us to increase productivity by machining five sides of the part in one setup.

TABLE SIZE: X-35.43” Y-30.7” Z-25.59”

MAX WORK ENVELOPE: Ø33 ” × H13 ” max weight 1100 lb

TOLERANCE: Tighter tolerances to ± 0.0002 available, depending on part geometry.

CMM INSPECTION

AD Precision is proud to have the latest technologies in quality control. From Zeiss to Mitutoyo, AD Precision has the ability to perform quality control along every step of the way in the production process. Our temperature controlled quality control areas assure that all tolerances are met to print.

TABLE SIZE: X-62.9” Y-94.5” Z-59.1”

MANUAL MILLING, TURNING ETC.

In addition to advanced CNC machining capabilities, our shop is fully equipped with conventional manual equipment to handle a wide range of manufacturing needs.

Our conventional services include manual milling, drilling, and turning for cost-effective part production when precision CNC is not required.

REPLACEMENT PARTS

We can produce high-quality replacement parts from samples or drawings, whether you need a single part or volume production.

We handle manufacturing in-house to reduce procurement time and costs, so you can focus on operations while we minimize your equipment downtimes.

What Our Customers Say

Where Quality Meets Affordability

Whether the project requires advanced technical expertise, tight tolerances, robust quality assurance, precise record keeping, or accelerated delivery times, AD Precision has the capabilities and dedication to fulfill it without exception. When industry leaders need certainty their needs will be met, they choose AD Precision first. Discover why we are the trusted manufacturing partner for no-compromise performance.

The Clear Choice for No-Compromise Manufacturing

Our obsessive attention to detail, rigorous processes, and steadfast commitment to perfection ensure we satisfy each client’s exacting demands from start to finish.

Whether the project requires advanced technical expertise, tight tolerances, robust quality assurance, precise record keeping, or accelerated delivery times, AD Precision has the capabilities and dedication to fulfill it without exception.

we engineer, machine, and manufacture high-tech products and make sure we not only meet–but exceed– our client’s precise and demanding requirements. We dedicate our time and talent to continuously improving company-wide.

Get in touch with Us

For more information on how AD Precision can help you achieve your manufacturing needs or for a quote, please fill out the form below or call (209) 222-2222.

2100 Standiford Ave,

Modesto, CA, 95350

United States of America

Phone : + 1 209 215 7070

Email : contacts@machiningpartner.com

Mon-Fri 9:00AM – 5:00PM

- 209-215-7070

- 2100 Standiford Ave, Modesto, CA, 95350

- Mon-Fri 9:00AM - 5:00PM

© 2023 All Rights Reserved. Sample 3-Axis Machine Shop Website